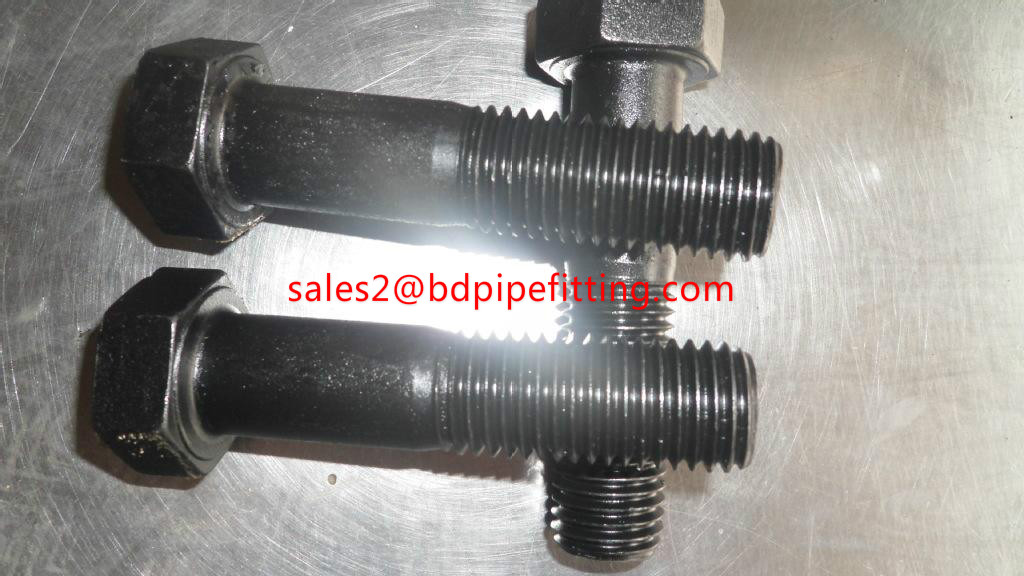

| Product Name | Hex Bolt |

| Material | Stainless Steel: SS201, SS303, SS304, SS316, SS410, SS420 |

| Carbon Steel: 4.8, 6.8, 8.8, 10.9, 12.9 |

| Titanium: GR1-GR5 |

| Aluminum,Brass,etc. |

| Size | M1.6-M39 Length: Up to 300mm |

| Head Type | Flat, JIS pan, Oval, Round, Binding, I.HD, Brazier, PF. HD, Button, Fillister, Ansi.Pan, Pan washer, Indented Hex etc |

| Standard | ISO,GB, DIN, JIS, ANSI, BSW, ASME

ASME B 18.2.1, IFI149,DIN931, DIN933, DIN558, DIN960, DIN961, DIN558, ISO4014 and etc. |

| Grade | SAE J429 Gr.2, 5,8; ASTM A307Gr.A, Class 4.8, 5.8, 6.8, 8.8, 10.9, 12.9 and etc. |

| Certificate | ISO9001:2008, SGS testing report & RoHS |

| Screw Drivers | Phillips, Slotted, Square, Crossed, Y-type, T-type, Torx, PZ drives, Hex socket etc |

| Finishing | Zn- Plated, Ni-plated, Tin-Plated, Radiant Plated, Passivated, Brass plated, Cd- plated, Phosphate Anodize, Cr-plated, Black Oxide etc |

| Heat Treatment | Tempering,Hardening,Spheroidizing,Stress Relieving etc |

| Package | General export package, or according to customer`s requirement |

| Delivery time | About 7 -15 days after all details confirmed and able to offering fast delivery for urgent order |

| Customer Service | Replacement at all our cost for rejected products if the part does not match with the PO drawings |