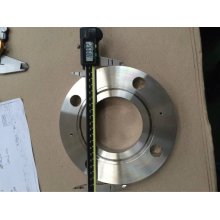

Bangdong Supply steel Weld Flanges.A pipe flange connects piping and components in a piping system by use of bolted connections and gaskets. Most commonly used flanges are Weld Neck Flange, Slip On Flange, Blind Flange, socket weld flange, threaded flange and Lap Joint Flange (RTJ Flange). This type of connection in a pipe flange allows for ease of disassembly and separation for repair and regular maintenance. Most common specification for carbon steel and Stainless Steel Flange is ANSI B16.5 / Asme B16.5.

Function of different types of flange:

- Weldneck flanges create a smooth weld matching the thickness and bevel of the pipe. With a diameter that matches the inside of the pipe, they work by transferring pressure from the flange to the pipe. Typically used for high-pressure applications, weldneck flanges are the most commonly used flange style.

- Threaded Pipe flanges are unique and beneficial because there is no need to weld them to the pipe. Instead, they have an outer thread. These are most commonly used for small diameter projects with high pressure.

- Slip-On flangesare the least expensive type and come in large or small sizes. They have a diameter slightly larger than the pipe, allowing them to easily slip directly over the pipe. After slipping on , they are then also fillet welded. The two types of slip-on flanges are the ring and hub flanges, differing by size specifications.

- Lap Joint flanges are typically used in conjunction with either a stub end or taft. Because it is easily assembled and aligned, this type of flange should be used in low-pressure applications or those that require frequent reassembling.

- Blind flanges, also known as blanking flanges, are used to seal off pipelines, pumps or valves to prevent flow. They are suitable for testing the pressure of liquid or gas flowing through a pipe and can sometimes be sued as an inspection cover. It is easily manageable and can be reversed to allow for expansion.

- Socket Weld flanges are used in high pressure, smaller pipe applications. Here, the pipe is inserted into the socket and fillet welded at the top allowing for a smoother fluid and gas flow through the pipe.

- Ring-Type Joint flanges can help in high-pressure applications to prevent leaks. These flanges have a unique groove that can be compressed onto a Slip-On, Blind or Weldneck flange. This will further allow the pipe to withstand extreme pressure and temperature.

Dimensions:

American Standard(ASME B16.5 & B16.47 Series A & B)

Size 1/2" - 20"

Pressure Rating 150#, 300#, 600#, 900#, 1500#, 2500#

Type SO, WN, LAP JOINT, SW, BL, THD, ORIFICE TYPE, REDUCING FLANGES

Facing RF, FF, RTJ, T&G

Material Grade A-105 / LF-2

F-5, F-9, F-11, F-22

304/L, 316/L, 321, 317/L, DUPLEX AND SUPER DUBLEX

904L INCONEL, MONEL, HASTEALLOY, ALLOY 20

DIN Standard:(17440/EN 1092-1)

Size 1/2" - 20"

Pressure Rating 150#, 300#, 600#, 900#, 1500#, 2500#

Type SO, WN, LAP JOINT, SW, BL, THD, ORIFICE TYPE, REDUCING FLANGES

Facing RF, FF, RTJ, T&G

Material Grade A-105 / LF-2

F-5, F-9, F-11, F-22

304/L, 316/L, 321, 317/L, DUPLEX AND SUPER DUBLEX

904L INCONEL, MONEL, HASTEALLOY, ALLOY 20

Forged Fittings

- Elbow

- Tee

- Reduction Tee

- Reduction

- Weldolet

- Sockolet

- Threadolet

- Elbolet

- Flangolet

- Latrolet

- Nipolet

- Couplings

- Forged Nipples

- Boss

MEASUREMENTS

ANSI B16.49 / DIN 2606 AND custom drawings

DIMENSIONS

½" – 216" / DN 10 – DN 5500

WALL THICKNESS

SCH 5S – SCH XXS

MATERIAL QUALITIES

ASTM A 234 WPA ‐ ASTM A 234 WPB ‐

ASTM A 234 WPC ‐ ASTM A 420 WPL6 ‐

WPHY 42/52/60/65/70

P235 – P265 – P245 – AE250 – ST 37 –

ST35.8

ASTM A 234 WP1‐ WP11 ‐ WP12 ‐ WP22 ‐

WP5 ‐ WP9 ‐ WP91 ‐ WP92 16 Mo 3,

13 CrMo 44, 10 CrMo 9 – 10

ASTM A 403 WP 304 / 304 L / 304 H

ASTM A 403 WP 321 / 321 H

ASTM A 403 WP 347 / 347 H

ASTM A 312 WP 316 / 316 L / 316 H/316 Ti

1.4301 / 1.4307 / 1.4541

1.4401 / 1.4404 / 1.4571

Duplex ‐ Super Duplex ‐ Inconel ‐ Incoloy ‐

Monel ‐ Hastelloy ‐ Titanium / Ti‐G

Product Categories : Steel Flange > Flanged Outlet