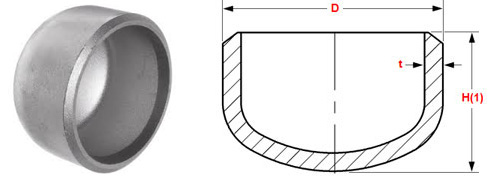

Butt weld Pipe Cap end. Butt weld pipe cap is one of our best sell products . We could supply Alloy steel butt weld pipe cap , ANSI Pipe End Cap , Asme B16.9 Cap,A234 End Cap Carbon Steel , Carbon steel ANSI END Cap ,MSS SP75 316L Pipe cap , ASME B16.9 Butt weld End Cap , A234Wpb pipe cap , WPHY70 Pipe end cap , Carbon Steel End Cap , Seamless Cap made from Plate , A234wp22 Butt Weld End Caps. If you require Pipe Fitting cap dimension , please kindly send to me .

We could manufacture carbon steel end cap according to your cap drawings .

Bangdong believes in long term relationship with our clients worldwide, Required Quality in reasonable price of ANSI/ASME B16.9 Butt weld End Cap are always our main priority. We are known as specialist in ANSI/ASME B16.9 Butt weld End Cap ,our customers are associated with us for their regular requirements of ANSI/ASME B16.9 Butt weld End Cap.

If you require buttweld end cap pipe fittings, SS ASTM A403 316L buttweld End Cap, SS ASTM A403 321, SS ASTM A403 347, SS ASTM A403 904L, Carbon Steel Astm A234 WPB, CS End Cap ASTM A234 WPHY 42, CS End Cap ASTM A234 WPHY 46, CS End Cap ASTM A234 WPHY 52, CS End Cap ASTM A234 WPHY 60, Alloy Steel End Cap ASTM/ASME A234 WP1, Alloy Steel End Cap ASTM/ASME A234 WP 5, Alloy Steel End Cap ASTM/ASME A234 WP 9, Alloy Steel End Cap ASTM/ASME A234 WP 11, Alloy Steel End Cap ASTM/ASME A234 WP 12, Alloy Steel End Cap ASTM/ASME A234 WP 22, Alloy Steel End Cap ASTM/ASME A234 WP 91 please contact us freely.

SPECIFICATION - ASME B16.9 SEAMLESS WELDING FITTINGS

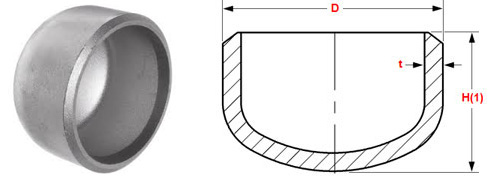

BUTT WELD END CAP

| Schedule: | Schedule 5S, 10S, 20S, S10, S20, S30, STD, 40S, S40, S60, XS, 80S, S80, S100, S120, S140, S160, XXS and etc. |

| Sizes: | 1/2"NB and over |

| Materials: | Stainless Steel End Cap – SS End Cap

ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

Carbon Steel End Cap – CS End Cap

ASTM A 234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

Low Temperature Carbon Steel End Cap – LTCS End Cap

ASTM A420 WPL3 / A420WPL6

Alloy Steel End Cap – AS End Cap

ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91 |

| Type: | Butt Weld (BW) |

| Dimension: | ANSI B16.9, ANSI B16.28, MSS-SP-43 Type A, MSS-SP-43 Type B, JIS B2312, JIS B2313 |

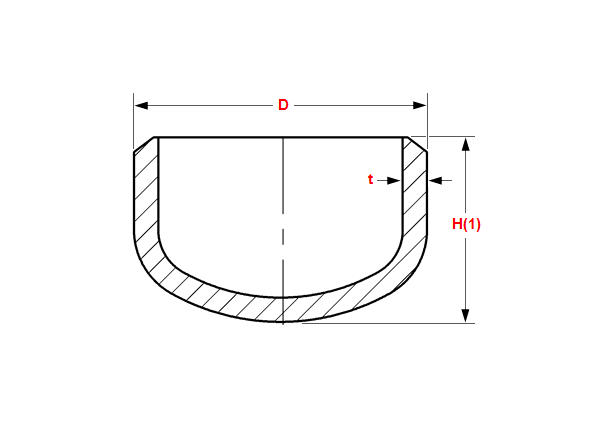

DIMENSIONS BUTTWELD END CAP

| NPS | O.D.

D | Len

H | W.T.

t | Len

H1 |

| 1/2 | 21.3 | 25 | 4.57 | 25 |

| 3/4 | 26.7 | 25 | 3.81 | 25 |

| 1 | 33.4 | 38 | 4.57 | 38 |

| 1¼ | 42.2 | 38 | 4.83 | 38 |

| 1½ | 48.3 | 38 | 5.08 | 38 |

| 2 | 60.3 | 38 | 5.59 | 44 |

| 2½ | 73 | 38 | 7.11 | 51 |

| 3 | 88.9 | 51 | 7.62 | 64 |

| 3½ | 101.6 | 64 | 8.13 | 76 |

| 4 | 114.3 | 64 | 8.64 | 76 |

| 5 | 141.3 | 76 | 9.65 | 89 |

| 6 | 168.3 | 89 | 10.92 | 102 |

| 8 | 219.1 | 102 | 12.7 | 127 |

| 10 | 273 | 127 | 12.7 | 152 |

| 12 | 323.8 | 152 | 12.7 | 178 |

| 14 | 355.6 | 165 | 12.7 | 191 |

| 16 | 406.4 | 178 | 12.7 | 203 |

| NPS | O.D.

D | Len

H | W.T.

t | Len

H1 |

| 18 | 457 | 203 | 12.7 | 229 |

| 20 | 508 | 229 | 12.7 | 254 |

| 22 | 559 | 254 | 12.7 | 254 |

| 24 | 610 | 267 | 12.7 | 305 |

| 26 | 660 | 267 | ... | ... |

| 28 | 711 | 267 | ... | ... |

| 30 | 762 | 267 | ... | ... |

| 32 | 813 | 267 | ... | ... |

| 34 | 864 | 237 | ... | ... |

| 36 | 914 | 267 | ... | ... |

| 38 | 965 | 305 | ... | ... |

| 40 | 1016 | 305 | ... | ... |

| 42 | 1067 | 305 | ... | ... |

| 44 | 1118 | 343 | ... | ... |

| 46 | 1168 | 343 | ... | ... |

| 48 | 1219 | 343 | ... | ... |

MARKING AND PACKING

Products are packaged to ensure that there is no damage during transit. In case of exports, standard export packaging is done in wooden cases. All flanges are marked with Grade, Lot No, Size, Degree and our trade mark. On special requests we can also, make custom marking on our products.

TEST CERTIFICATES

Manufacturer Test Certificate as per EN 10204 / 3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report

USES & APPLICATION

| Chemical | Oil Mills | Petrochemical | Mining | Refineries | Construction |

| Fertilizers | Shipbuilding | Power Plant | Steel Plant | Nuclear Power | Offshore |

| Oil & Gas | Defence | Paper | Ports | Breweries | Railway |

| Cement | Engineering Co. | Sugar & | Government Org. etc. |

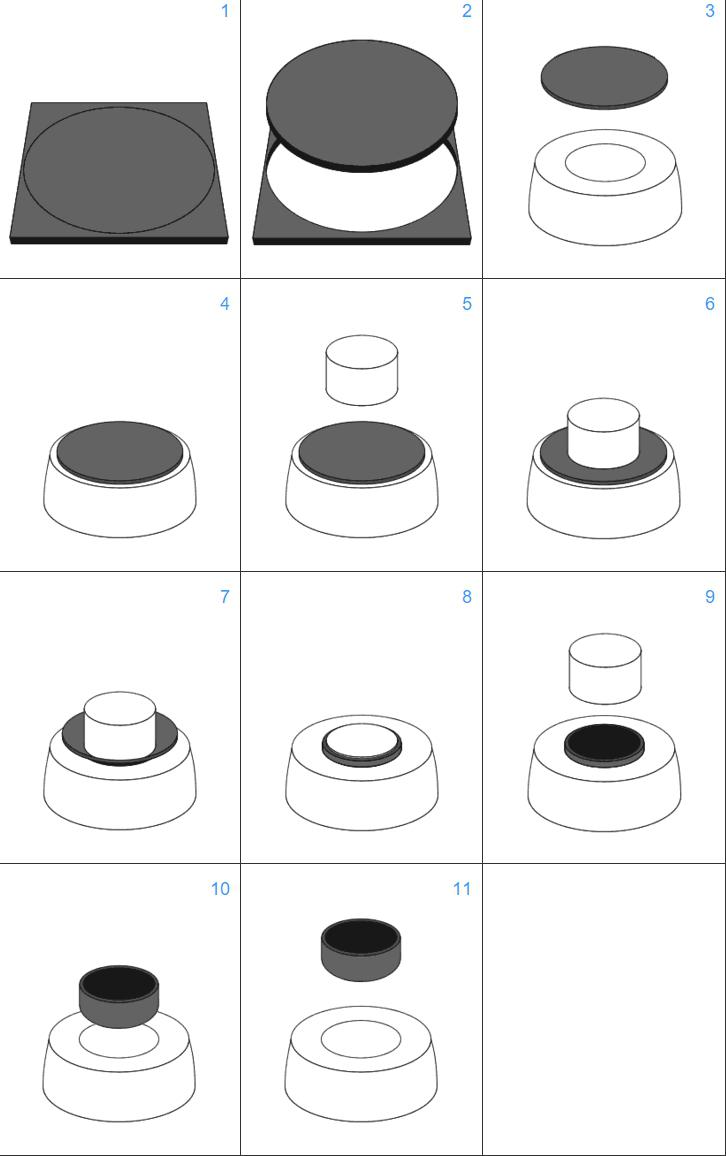

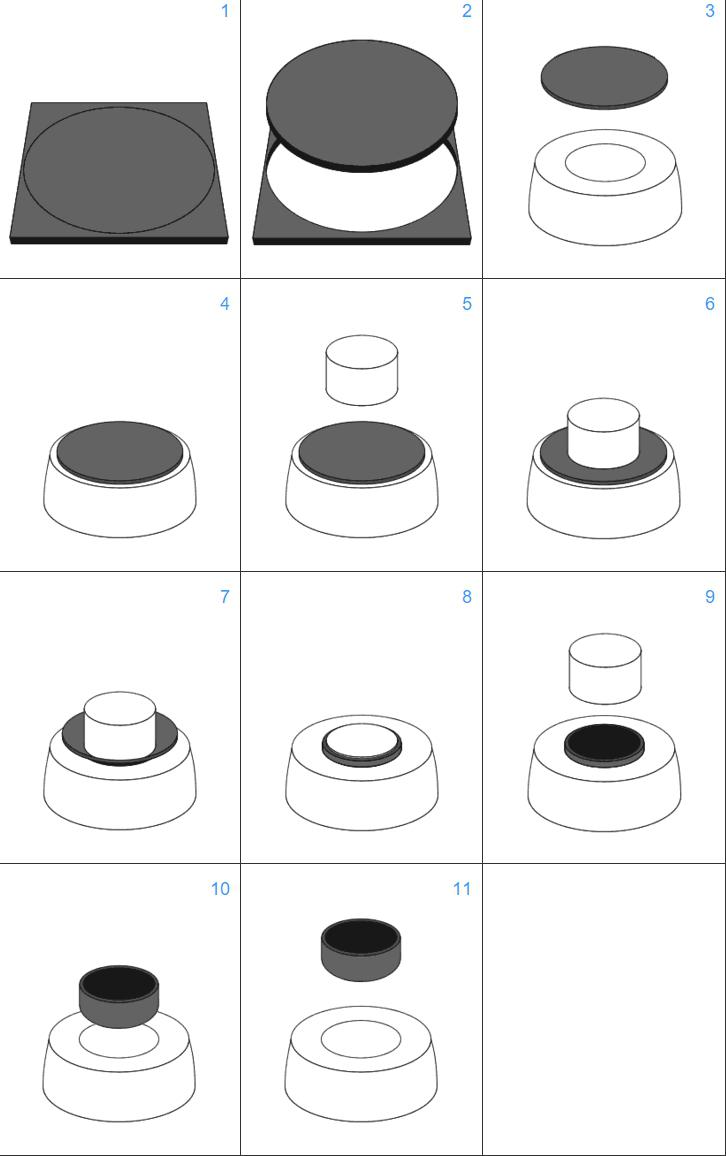

Manufacturing of Butt Welded CAPS

Introduction to Hot Forming

The principal methods of hot working are extrusion, drawing, forging and rolling. Rolling is the most extensive employed forming process, though some limitations may apply to the process. Rolling mainly consists of three major sub-categories: flat rolling, shape rolling (with specifically designed roll grooves) and pipe rolling (including piercing). Forging may be sub-categorized as hamming, pressing, etc.

Forging may be performed under hammers, in mechanical presses and up setters or by a method known as roll forging. Pressing generally includes the manufacture of forged articles in hydraulic presses. Extrusion usually is performed in hydraulic presses which force the hot steel through a die. Rolling is performed in rolling mills of a variety of types.

The two principal reasons for perform metal forming at elevated temperatures (hot working) are to reduce the forming loads through the reduction of the resistance of the steel to deformation, and to develop preferred metallurgical structures for strength and ductility of the finish products.

The most appropriate manufacturing method of a product will be decided with consideration of its material, sizes, shape, use, standards and other properties.

There are numerous processes for manufacturing butt weld fittings, several examples listed as follows.

CAPS: Deep Drawing method

One of the most common manufacturing methods for caps, where plate is cut out in a circle and formed by deep drawing.

Deep drawing is the manufacturing process of forming sheet metal stock, called blanks, into geometrical or irregular shapes that are more than half their diameters in depth. Deep drawing involves stretching the metal blank around a plug and then moving it into a moulding cutter called a die.

A drawing press can be used for forming sheet metal into different shapes and the finished shape depends on the final position that the blanks are pushed down in. The metal used in deep drawing must be malleable as well as resistant to stress and tension damage.

A234 End Cap in stock :

A234WPB End cap

A234 WP91 End cap

A234 WP9 End cap

A234 WP11 End cap

A234 WP1 End cap

A234WP5 End cap

A234WP12 End cap

If you require any pipe cap or carbon steel cap , please feel free to contact , we will offer the best to you .

Product Categories : Butt Weld Pipe Fitting > Pipe Cap/Nipple/Coupling